Hydrodynamics and Mass Transfer Simulation in Airlift Bioreactor with Settler using Computational Fluid Dynamics

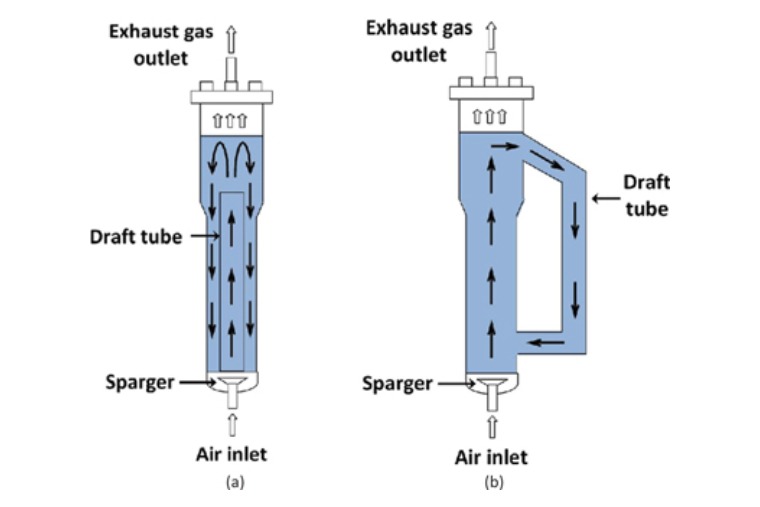

In this work, the effect of inlet-gas superficial velocity over the circulation liquid velocity, gas holdup and mass transfer, from an airlift bioreactor with settler were studied by Computational Fluid Dynamics (CFD) model- ing and contrasted with experimental results. Multiphase mixture model and κ-ε turbulence model were used to describe the two phases gas-liquid flow pattern in airlift bioreactor. The hydrodynamic parameters such as liquid circulation velocity and gas holdup were computed by solving the governing equations of continuity, moment and turbulence transport using the finite volume method. Global mass transfer coefficient was eval- uated through the Higbie’s penetration theory and the two-phase fluid dynamic theory. Comparison between our numerical data and experimental data previously reported in the literature was done. Numerical and ex- perimental data were very close, and the differences found were discussed in terms of the limitations of this study.

Fuente: ResearchGate